January 2025

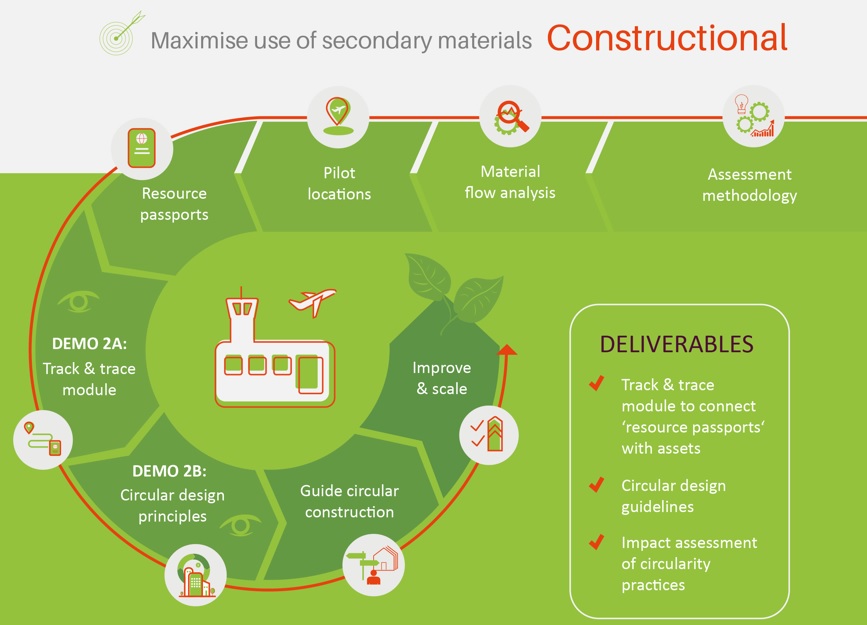

You might not expect it, but construction materials form a significant waste stream at an airport like Schiphol. Or rather, a stream of resources, as TULIPS Work Package 6 views it. Applying circular economy practices with construction materials therefore makes sense, as these are accountable for almost 40% of global CO2 emissions. Schiphol, EME (Excess Materials Exchange) and Heijmans have taken the first steps in filling a materials marketplace for Schiphol, to accelerate the transition to a circular economy. The first 100 items have been uploaded and claimed for reuse.

From baseline to marketplace

At Schiphol, constant construction and maintenance projects take place, whether it’s runway maintenance, terminal renovation, or relocating a checkpoint. TULIPS has been very active in developing and testing solutions to identify and categorise different types of construction materials at airports using digital passports. This work has created an improved baseline for their recycling, reuse, or lifetime extension. However, materials will only turn into resources once they are accessible to potential users. The next logical step was, therefore, to implement and test a digital marketplace that serves precisely this function. To this end, Schiphol, EME, and Heijmans – one of Schiphol’s strategic partners – have engaged in a joint project to develop and populate a materials marketplace for Schiphol, to accelerate the airport’s transition to a circular economy.

Materials marketplace

To clearly identify and facilitate the reuse of available materials, Schiphol’s excess materials are listed on the EME platform. Each material is assigned a product passport and then digitally placed on the EME platform, which functions as a ‘resale as a service (RAAS)’ solution tackling resource inefficiency. Project managers can act as suppliers by listing assets on the platform or as buyers by viewing and reserving available materials in real-time for their construction projects.

Tagging and tracing

A prerequisite for the EME platform is tagging and tracing of the materials. First and foremost, this gives them an identity by means of a product passport, something that the EU is also aiming to push. The specifics in the passports, together with the built-in AI and machine learning of the platform make it easier for buyers to search for materials. For the pilot, materials are therefore provided with a tag, for example QR codes, smart RFID or low energy bluetooth.

First applications a reality

Heijmans and Schiphol are using the EME platform for Schiphol’s excess materials. Many materials have already been entered via the platform, and over 100 items have been reserved for projects. Heijmans carries out the actual reuse by providing materials from storage and reusing these materials in its projects. In the coming period, more materials will be added and more partners will be involved.

Pilots at Oslo and Cyprus

TULIPS partners Oslo Airport (Avinor) and Larnaca Airport (Hermes) have initiated similar pilots with the EME RAAS solution. In Oslo, the platform was used for following materials during the disassembly of a gate, temporarily storing the materials, and constructing a new gate using as many reused materials as possible. Larnaca utilised the platform to monitor the progress of their office remodeling work. Testing the platform at different airports will enable us to gather valuable lessons and provide sound advice for European airports aiming to adopt circular practices.

The goal: Seamlessly connect supply and demand

The aim is to seamlessly connect supply and demand via the platform to reduce waste,maximise reuse of materials and unlock the highest value for excess materials. This is not only more sustainable but will also become increasingly important economically over time as we expect materials to become scarcer and therefore more expensive.